-

Service & Technical

- BD & Tradewinds 12/24 VDC

- Baitfreezer 110/220 VAC

- BG 1000 110/220 VAC

- BG 2000 110/220 VAC

- Cool Fish RSW Chiller

- DC 5000 12/24 VDC

- Engine Drive Refrigeration

- Engine Drive Air

- Shore Assist 110/220 VAC

- Our Products

- Price List

- Miscellaneous

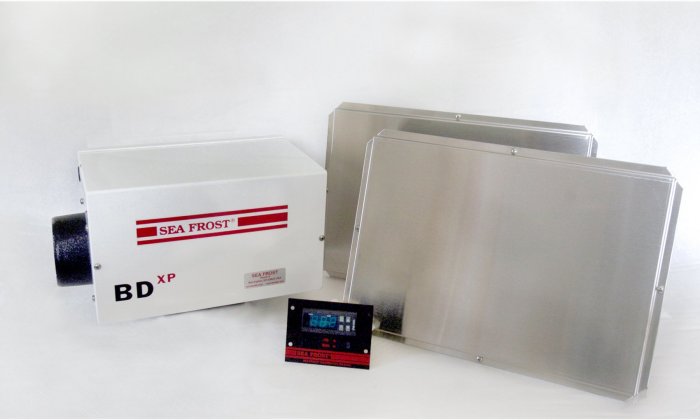

Sea Frost BD Series

12/24 Volt Refrigeration Systems

The Sea Frost BD Direct Evaporator System is an advanced design that will operate on 12- or 24- volt D.C. power. It is perfect for well insulated refrigerator boxes. The system consists of two components — the compressor, which is remotely located, and the stainless steel cold plate. The two components are connected by pre-charged copper lines attached at the plate. The rugged, half-inch thick polished stainless steel cold plate can be mounted on a shelf, wall or ceiling and offers the highest resistance to damage and corrosion. Optional ice-making trays are available for wall-mounted installations.

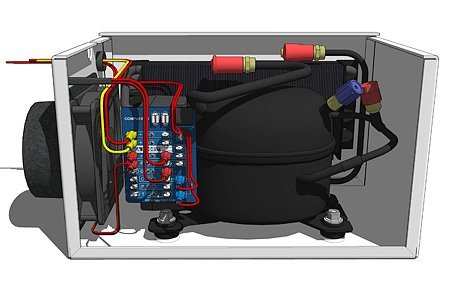

BD systems are factory pre-charged and require no special tools for installation. Popular Danfoss® hermetic compressors are used in both the BD and BDxp. These electronically-controlled, variable speed compressors feature state of the art efficiency. BD compressors are totally enclosed with a brushless D.C. fan and efficient, oversized copper and aluminum finned condenser. Ducted air cooling creates the highest efficiency and allows for installation in confined locations.

BD Systems

Sea Frost's BD is well-suited for boats with adequate battery banks and charging equipment. Thermostatic operation maintains the cold plate at even temperatures. The thin direct evaporator cold plate requires minimal box space. Dockside, the system operates through the boat's battery charger.

Options include custom plate sizes, custom line lengths, 2-plate freezer systems, freezer bin, remote thermostat, electronic thermostat with speed control, air and water cooling and ice-making tray kits.

Compressor Information

All BD systems feature ducted air cooling. The four-inch round intake vent is ducted to the cabin to allow the compressor to draw in ambient temperature air. This air is then forced through the compressor box to cool the electronics and pass through the oversized air cooled condenser. Exhausted air exits through the back side of the cabinet ensuring efficient performance even in tropical climates.

- Height: 7.5 inches

- Width: 15 inches (includes 4-inch air duct)

- Depth: 9 inches

- Weight: 19 lbs.

Compressor Dimensions

The BD comes pre-charged with R-134a refrigerant. The copper lines from the cold plate connect to the compressor with brass Aeroquip® connectors which are self-sealing and may be disconnected without loss of refrigerant. The compressor is fitted with SAE-style R-134a service ports.

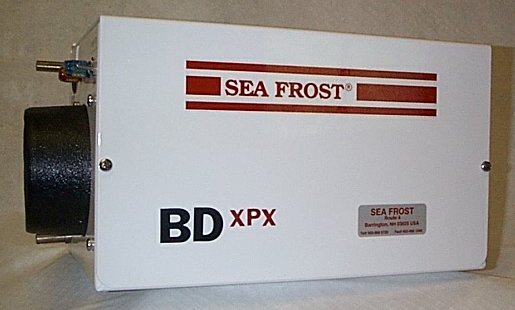

BDXP Systems

The BDxp is has approximately 30% more capacity than the standard BD. The BDxp should be used in larger refrigerator and freezer applications. The BDxp has an AEO (Adaptive Energy Optimizing) feature. This feature senses the amount of cooling needed and adjusts compressor speed accordingly. The BDxp may be fitted with a speed control in order to manage power draw. Air cooling is standard; optional air and water cooling is available. Housing size and weight are identical to the BD.

See charts on amp draw and compressor capacity.

BDXPXAW Systems

The Sea Frost BDxpxAW is the highest capacity BD system. Ideally suited for low temperature freezers and the largest refrigerators. The BDxpxAW is coupled with stainless steel direct evaporator plates that can be custom sized for optimum performance.

Condensing Unit Dimensions:

- Height: 7.5 inches

- Width: 15 inches (includes 4-inch air duct)

- Depth: 9 inches

- Weight: 19 lbs.

Ducted air and selectable water-cooling give the BDxpxAW excellent efficiency and allow maximum capacity operation in all installations.

The BDxpxAW is fitted with a Danfoss® variable speed brushless hermetic compressor. Automatic speed control using AEO or optional manual speed control. All systems are pre-charged with refrigerant R-404a.

Stainless Steel Freezer Bin

For a small freezer within a refrigerator, the stainless steel freezer bin is ideal. Two walls of the Freezer Bin are double sided direct evaporator cold plates which freeze the bin on the inside, creating a small freezer, and refrigerate the cabinet.

The bin should be mounted high in the box, either vertically or horizontally, and operates best in a relatively small, well insulated cabinet. The standard built-in thermostat regulates the compressor to maintain constant temperatures. Other options include a remote thermostat, Electronic Thermostat Thermometer with speed control, stainless steel door, starboard bin lid and ice making tray kit. Custom widths are also available up to 12 inches.

The bin should be mounted high in the box, either vertically or horizontally, and operates best in a relatively small, well insulated cabinet. The standard built-in thermostat regulates the compressor to maintain constant temperatures. Other options include a remote thermostat, Electronic Thermostat Thermometer with speed control, stainless steel door, starboard bin lid and ice making tray kit. Custom widths are also available up to 12 inches.

Click here to see available Bin sizes.

Thermostats and Controls

Remote Thermostat

The optional Remote Thermostat is panel mounted. This control allows adjusting the temperature or switching on/off of the BD without having to open the box. The thermostat must be mounted within 50 inches of the cold plate.

- Height: 3.5 inches

- Width: 3.15 inches

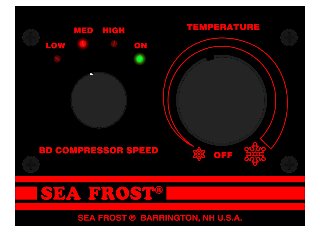

Electronic Thermostat/Thermometer with Speed Control (ETTsc)

The Electronic Thermostat Thermometer with Compressor Speed Control (ETTsc) for our Danfoss compressor-based BD series of refrigeration and freezer systems. This new control allows accurate temperature control, cabinet temperature monitoring, and compressor speed selection. On the larger compressors the AEO (automatic energy optimization) can be selected or set at a fixed speed.

Compressor speed can be set to match the compressor amp draw to solar panel outputs, or set for weather regions and seasons, or help to manage battery discharge rates when offshore and all electronics are in use.

The ETT is pre-wired with plug in connectors for the two 10' temperature probes and a 20' cat 5 data cable with RJ 45 connectors. Custom length data cable available. Wire leads allow mounting any distance from cabinet.

- Height: 3.5 inches

- Width: 4.6 inches

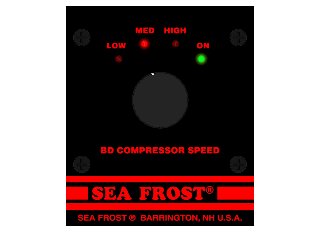

BD Speed Control

The BD Speed Control can be added to any BD system to change the compressor speed. Speed can be adjusted for cooler weather and will reduce cycling of the compressor. Slowing the compressor reduces the cooling rate, lowering amp draw and reducing battery wear. This also allows energy draw to be matched to solar panels or windmill output. LEDs indicate the compressor operation and speed. The BD speed control should be used with the standard thermostat or with older versions of the ETT (without the built in speed control.)

- Height: 3.5 inches

- Width: 3.15 inches

BD Speed Control/Thermostat

The BD Speed Control/Thermostat combines the Remote Thermostat with a speed control. The thermostat must be mounted within 50 inches of the cold plate.

- Height: 3.5 inches

- Width: 4.6 inches

Options

Water Cooled Option

The water cooling option, added to the BD air and BDXP air cooled systems, incorporates a copper-nickel tube-in-tube condenser. A remote pump, elected by a switch on the cabinet, operates with the compressor and fan. Water cooling should be used in engine room or other confined installations. This type of condenser utilizes the scrubbing effect of water and is far more efficient than static water cooling.

Water cooling is standard on the BDXPX systems.

Brushless Magnetic Drive Water Pump

- 12 & 24 Volt Available

- One Pump Can Drive Several Units

- Stainless Steel Mounting Bracket

- Height: 2.96 inches

- Width: 2.45 inches

- Length: 4.46 inches

- Inlet 1/2" Hose

- Outlet 3/8" Hose

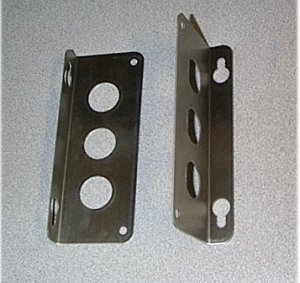

Bulkhead Mounting Brackets

Stainless steel bulkhead brackets are available for mounting the BD compressor cabinet to a vertical wall.

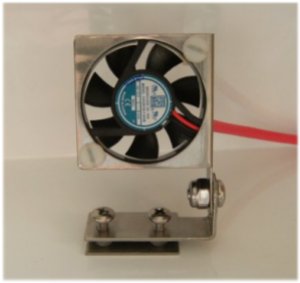

Plate Mounted Fan Widget

The Fan Widget will clamp to the edge of any of our BD plates. The air can be directed toward the cold plate to scrub cold air away. This effectively increases the plate cooling capacity.

The Fan Widget will clamp to the edge of any of our BD plates. The air can be directed toward the cold plate to scrub cold air away. This effectively increases the plate cooling capacity.

The Fan Widget can also blow air up or down in the cabinet to stir the air making the box temperature even from top to bottom. The bracket allows alternate mounting to the box wall by removing the two machine screws and fastening with # 6 self-tapping screws.

Click here for more information on the Fan Widget.

Ice-making Kits

Ice making trays are an option. Ice can be made with both refrigerator and freezer applications. The trays are specially made to expand when the water freezes to ice. The ice trays hang on the vertical sides of the cold plate in surface contact. Removing the frozen trays from the cold plate and allowing them to melt slightly will allow the cubes to be harvested and stored for later use. Each vertical tray kit includes two vertical trays and splines, mounting rod and clips.

Plate Sizing for Refrigerators

BD systems use thin (half-inch), stainless steel cold plates. These direct evaporator plates provide excellent thermal conductivity for cooling efficiency. They're mounted on stand-offs to allow air to flow on both sides. Refrigerators require a single plate which should be mounted as high as possible in your insulated box. Approximately 20% of the wall area should be covered.

Click here to see available plate sizes.

Plate Sizing for Freezers

Consider the freezer as an additional system with its own compressor and controls. This is the best way to achieve deep freeze temperatures.

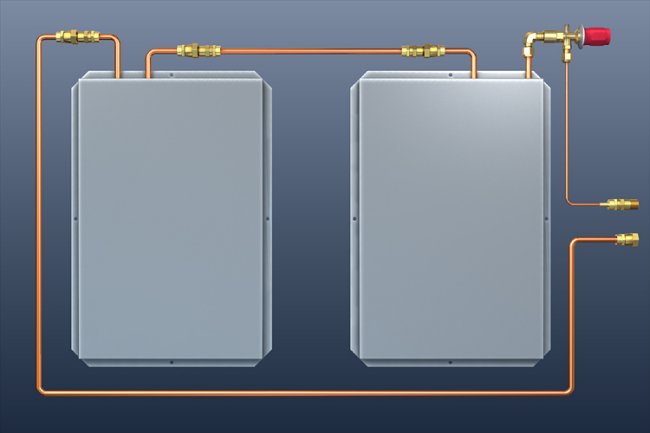

It is necessary to have more plate area in a freezer to get air temperatures close to plate temperatures. Freezers require two plates in series, mounted on opposite walls of the same box to create a sandwiching effect. This helps eliminate problems with air flow in a full box. 60% of the wall area should be covered. In series systems, a small copper line from the compressor runs to the first plate where an expansion valve is mounted. An inter-connector jumper connects the first plate to the second plate; a return line connects the second plate to the compressor.

| Plate layout - Figure A | Plate layout - Figure B | Plate Layout - Figure C |

|---|---|---|

|

|

|

All our systems are built to your specifications. Custom plate sizes and custom tube lengths are available. Plates can be mounted either horizontal or vertical to fit the configuration of your box.

Click here to see available plate sizes.

To order a system, the following information is required:

- Plate dimensions and orientation. Both standard and custom plates available.

- Location of valve on plate.

- The distance between the two plates for the length of the connecting jumper line.

- Liquid line length. (Distance between valve on the first plate in the series and the compressor.)

- Suction line length. (Distance between the second plate in the series and the compressor.)

Installation and Use

The insulated cabinet is a big factor in the success or failure of a refrigeration system. Heat leaks into a chilled box. This heat is what must be removed on a continuous basis. Energy usage or compressor amp draw is all based on the amount of cooling needed (heat leaking in). This energy usage is based on box size, the insulation type and thickness, and the climate the boat is in. Heat travels into the cabinet from all directions so it is important to have a well insulated top and lid. Cold air will flow like water. All drains need to be plugged to prevent losing cold air. Lids require good air seals.

Inside a refrigerated box, temperatures will be lower at the bottom. Mounting a cold plate at the top cools the warmer air and the box more evenly. Sometimes fans help even out the temperature.

Air is the medium that transfers the cooling from the cold plate to the food. Shelves should be vented to allow air to flow. A grating or baskets should be used to allow air to flow around the food. This is important in a freezer. Packing a boat refrigerator may require putting the lettuce at one end away from the cold plate and the beer and milk at the bottom or near the plate.

Frost build up on cold plates will reduce the efficiency of the system. This frost is a product of humid conditions and wet products being refrigerated.

| BD | BDxp | BDxpx | |

|---|---|---|---|

| Voltage | 12 Volts | 12 Volts | 12 Volts |

| Fuse Size | 15 Amps | 30 Amps | 30 Amps |

| Maximum Amp Draw (air 90° F.) | 5.6 Amps | 7.7 Amps | 8.5 Amps |

| Draw @ Medium Speed | 3.4 Amps | 5.4 Amps | 6.7 Amps |

| Draw @ Low Speed | 2.6 Amps | 4.5 Amps | 5.1 Amps |

| BTU's @ Max Speed (ASHRE) | 250 BTU's (Evaporator -10° F) | 363 BTU's (Evaporator -10° F) | 354 BTU's (Evaporator -30° F.) |

| Water Pump (optional) | 1 Amp | 1 Amp | 1 Amp |

Compressor efficiency is about 3.5 to 4 BTU per watt in tropical climates. The BD compressors are variable speed; at low speeds there is low amp draw but a low cooling rate. Higher compressor speed results in more cooling but more amp draw as well. Amp draw is therefore directly related to the amount of cooling being produced and is not the way to compare system performance.

Energy Conversion Estimates

- A 2.3 cubic foot (16" x 16" x 16") box with 3" of 2 lb. density foam insulation used as a refrigerator in the tropics will use 25 amp/hours @ 12 volts per day.

- An 8 cubic foot (24" x 24" x 24") box with 3" of 2 lb. density foam insulation used as a refrigerator in the tropics will use 57 amp/hours @ 12 volts per day.

- A 15.6 cubic foot (30" x 30" x 30") box with 4" of 2 lb. density foam insulation used as a refrigerator in the tropics will use 68 amp/hours @ 12 volts per day.

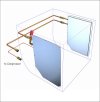

Diagram of an Air Cooled Installation

Click on picture to view full size version.

Ducted air cooling creates the highest efficiency and allows installation in confined areas such as a sail locker, or under a cabinet or seat. The ducting eliminates re-circulation of the cooling air. The air temperature increase is minimal (2° to 3° F.). Air flow can be reversed.